How CAM Shapes the Future of Mechanical Engineering

In modern manufacturing, CAM in Mechanical Engineering has revolutionized the role of mechanical engineers. With industries demanding precision, efficiency, and faster production cycles, understanding CAM is no longer optional—it is crucial. Mechanical engineers equipped with CAM skills can seamlessly bridge the gap between innovative design and flawless manufacturing. This article explores CAM in depth, highlighting its importance, advantages, software tools, and future potential for mechanical engineers.

CAM in Mechanical Engineering

Defining CAM and Its Core Functions

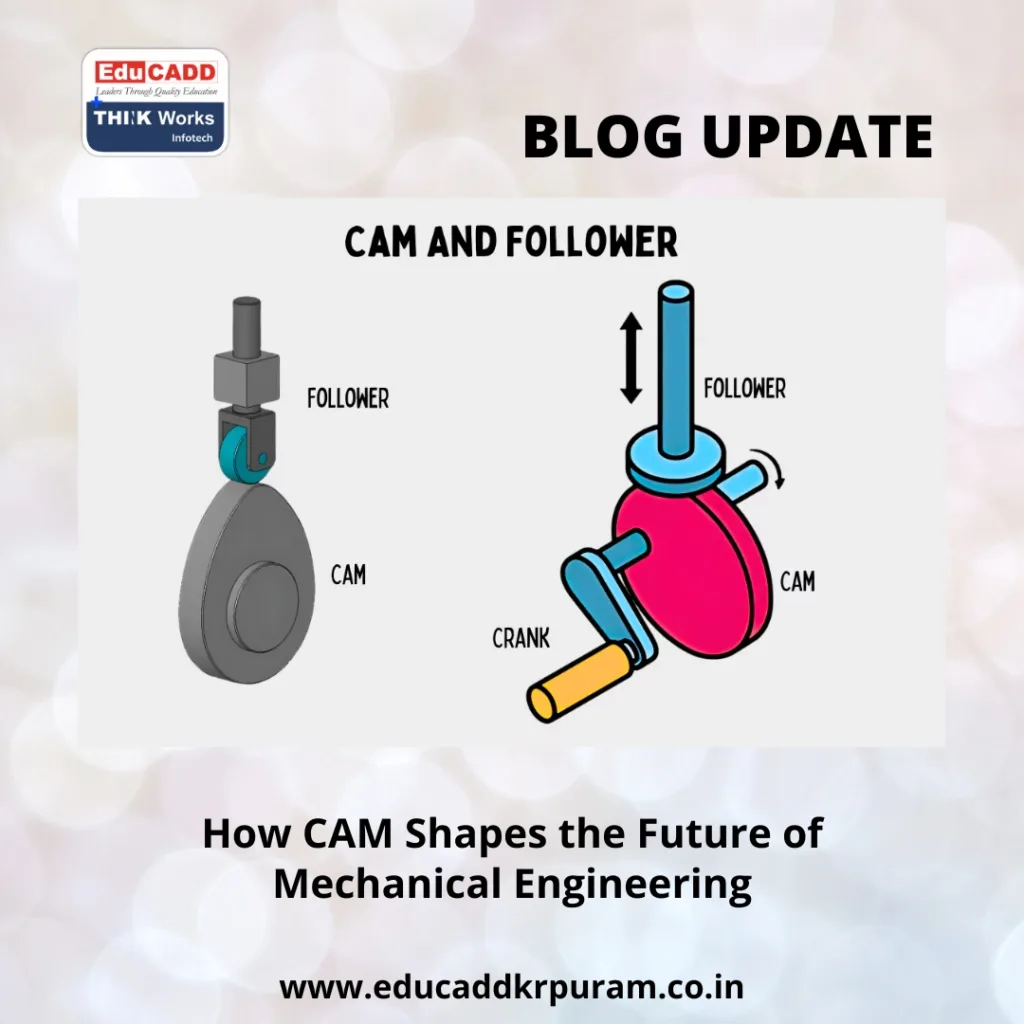

Computer-Aided Manufacturing (CAM) is the process of using computer systems and software to control machine tools and related machinery. Unlike traditional manual operations, CAM integrates digital design with production, ensuring efficiency, precision, and consistency.

CAM software interprets designs created in CAM in Mechanical Engineering programs and generates accurate instructions for machines, including CNC machines. It allows engineers to plan toolpaths, simulate machining operations, and identify potential production errors before physical manufacturing begins.

For mechanical engineers, understanding CAM provides the ability to evaluate design feasibility, optimize production, and deliver high-quality products. CAM supports a wide array of manufacturing techniques, from milling and turning to additive manufacturing, enabling engineers to handle complex and precision-driven projects efficiently.

Why CAM Is Critical for Mechanical Engineers

Mechanical engineers are responsible for designing and producing mechanical systems that meet strict standards. Integrating CAM into their workflow has transformed traditional engineering approaches, improving speed, precision, and product quality.

Key benefits of CAM for mechanical engineers include:

-

Enhanced Accuracy: CAM ensures designs are executed with precision, minimizing human errors.

-

Efficient Production: Automated operations save time and reduce the effort required for complex tasks.

-

Design-to-Production Integration: CAM bridges CAD and manufacturing, enabling a smooth transition from design to production.

-

Support for Complex Designs: CAM software can manage intricate geometries that are challenging to produce manually.

-

Predictive Problem-Solving: Virtual simulations allow engineers to detect and correct potential production issues in advance.

Mechanical engineers who adopt CAM gain not only technical expertise but also a strategic advantage in the competitive engineering landscape. Their ability to oversee the complete production process—from design to final product—enhances project outcomes and efficiency.

Benefits of Learning CAM for Career Growth

Mastering CAM offers mechanical engineers substantial career advantages. These benefits span across professional development, operational efficiency, and innovation.

1. Higher Employability:

Industries like aerospace, automotive, and industrial manufacturing prioritize engineers with CAM expertise. It opens doors to roles in design, production planning, and manufacturing management.

2. Precision and Speed:

CAM automates toolpath generation and machining operations, reducing manual errors and accelerating production cycles. Engineers can simulate the entire process before initiating actual manufacturing.

3. Cost Efficiency:

By reducing material waste and minimizing machine downtime, CAM contributes to significant cost savings for companies. Engineers who implement CAM effectively increase organizational value.

4. Innovation Opportunities:

CAM allows mechanical engineers to experiment with complex designs safely, fostering creativity and enabling cutting-edge product development.

5. Improved Collaboration:

Modern CAM platforms integrate with CAD and PLM systems, allowing engineers to share design files, manufacturing plans, and updates seamlessly with colleagues, reducing errors caused by miscommunication.

Learning CAM transforms mechanical engineers into versatile professionals capable of handling design, production, and problem-solving simultaneously.

Essential CAM Software for Mechanical Engineers

Mechanical engineers benefit greatly from hands-on experience with leading CAM software. Familiarity with these tools ensures smooth execution of design-to-production processes.

-

Mastercam: Popular for CNC programming, it offers an intuitive interface for milling, turning, and advanced machining operations.

-

Siemens NX CAM: Provides comprehensive solutions for manufacturing, including simulation, production planning, and toolpath optimization.

-

SolidWorks CAM: Integrates seamlessly with SolidWorks CAD, allowing engineers to design and produce components within one ecosystem.

-

CATIA CAM: Preferred in automotive and aerospace industries, CATIA supports complex geometries and high-precision manufacturing.

-

Fusion 360: Cloud-based platform combining CAD, CAM, and CAE, suitable for collaborative projects and rapid prototyping.

Proficiency in these software tools enhances mechanical engineers’ ability to innovate, optimize workflows, and deliver superior quality products. Beyond technical knowledge, understanding CAM principles allows engineers to select the right software and approach for each unique project.

Future of CAM in Mechanical Engineering

CAM continues to evolve with emerging technologies, reshaping the way mechanical engineers design and manufacture products. Staying updated with these trends is crucial for maintaining a competitive edge.

1. Industry 4.0 Integration:

Smart factories now connect CAM systems with IoT-enabled machinery, enabling real-time monitoring and predictive maintenance.

2. Support for Additive Manufacturing:

Modern CAM platforms accommodate 3D printing and hybrid manufacturing methods, expanding possibilities for prototyping and production.

3. AI-Enhanced CAM:

Artificial intelligence in CAM optimizes toolpaths, reduces errors, and increases efficiency without manual intervention.

4. Cloud-Based Collaboration:

Engineers can access CAM platforms remotely, perform simulations, and collaborate on complex designs from any location.

5. Sustainable Manufacturing Practices:

CAM supports environmentally responsible manufacturing by reducing waste, conserving energy, and optimizing material usage.

Mechanical engineers who embrace these trends will not only improve operational efficiency but also play a leading role in innovation and sustainable production practices.

Conclusion: CAM as a Core Competency for Mechanical Engineers

CAM in Mechanical Engineering has fundamentally transformed the role of mechanical engineers. By learning CAM, engineers enhance precision, improve efficiency, and gain the ability to transform innovative designs into tangible, high-quality products.

Understanding how CAM shapes the future of mechanical engineering is essential for anyone seeking long-term career success in modern manufacturing industries. CAM equips engineers with skills that make them invaluable contributors to product development, production planning, and process optimization.

Mechanical engineers who invest in mastering CAM remain competitive, versatile, and ready to tackle the challenges of advanced manufacturing technologies. CAM is no longer a supplementary skill; it is a cornerstone of engineering excellence.